A Beginner’s Guide to Fracking Pumps

The oil and gas industry has been using frac pumps to perform vertical drilling for decades. However, traditional frac pumps do not provide enough power to drill through shale rock formations, which is necessary for modern hydraulic fracking and horizontal drilling.

Modern frac pumps require better lubrication mechanisms to function in higher pressures and for longer hours within minimal downtime. In this guide, we’ll take a closer look at different types of frac pumps and applications. We’ll also explore new technologies as they relate to hydraulic fracturing treatments.

What Are Frac Pumps?

Frac pumps are diesel-engine-powered fracturing equipment used in hydraulic fracturing of shale rock formations to extract the trapped oil and gas. With fracking technology thriving across the US, frac pumps that can pump fracking fluid down the wellbore (water, silica sand, and fracking chemicals) are in high demand.

How Does a Fracking Pump Work?

Frac pumping equipment consists of reciprocating positive displacement pumps with a fluid end and a power end. They endure the stress of harsh hydraulic fracturing fluids and the high-pressure pumping of fracking fluid down the shaft.

Pumps prevent the liquid from shooting back up the shaft by overpowering its pressure. This fluid helps develop 200 ft. - 400 ft. cracks in the shale rock. These cracks act as channels for oil and natural gas to flow upwards through the shaft.

Common Types of Frac Pumps

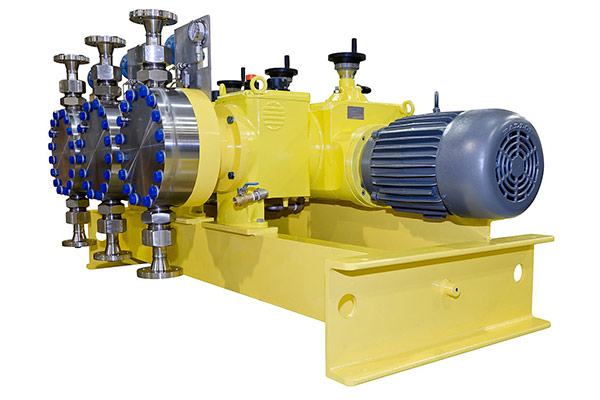

Triplex Pumps

They are typically 2,550 bhp reciprocating positive displacement pumps that can handle a wide range of fluids, including corrosive fluids, abrasive fluids, and slurries containing large particulates. They use three pistons or plungers operating in cylinders using a single power source. The reciprocating motion of the plungers creates pulsations to pump low and high viscous liquids into a well.

They work on the same principle as an internal combustion engine converting the rotation of the motor shaft to the reciprocating motion of pistons and plungers. With three pistons, it is possible to make the flow smoother with reduced pressure pulsations and fatigue on the pump’s components.

Smaller triplex pumps are used in car washes and commercial and industrial wash stations. Larger triplex pumps are used in oil drilling and oil well service.

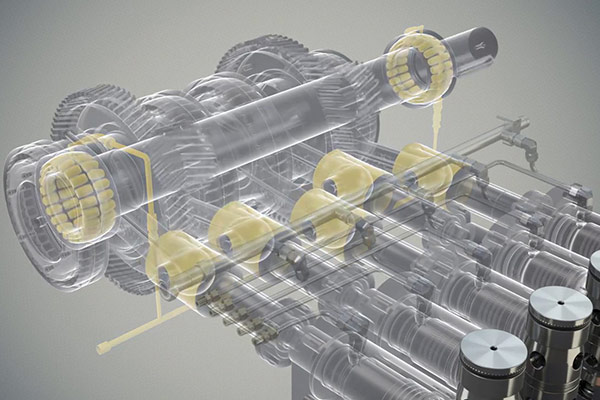

Quintuplex Pumps

These 5,000 bhp high-power stainless steel pumps are specially designed for frac fleets in hydraulic fracturing. They help realize better efficiency and cost savings in consumables during pressure pumping. It reduces the number of trucks required in the fleet and allows lower operational speed with longer life and reduced fatigue cycles. In addition, it shows reduced downtime with better serviceability in the field.

Quintuplex pumps reduce the noise pollution to almost half, making the long working hours of the personnel safer. The flow in quintuplex pumps varies between 94% and 102% (8% variation) of the average flow rate compared to 82% to 107% (25% variation) in triplex pumps.

Frac Pump Applications

Coiled Tubing

Tubing is fed down the shaft with a mechanical or hydraulic injector. This tubing carries various fluids that help extract oil and gas. With longer vertical and horizontal lengths of drilled shafts, longer tubing runs are necessary. With this, we need greater pump capability to create the pressure required to get the job done. The pumps can be mounted on a skid, truck, or trailer.

Acidizing

Optimal production of oil and gas from the well is vital, and acidizing is one of the most widely used techniques to do so. Pumping acid down the shaft during the initial stimulation and fracturing process provides a clean bore, enhances fractures, and dissolves any materials that may block the pathway.

In heavy-duty acidizing treatments (acid frac, matrix acidizing, acid stimulation), the success of the treatment depends on the pressure and flow rate of the servicing pump.

Fracturing

Pressure pumps for hydraulic fracturing operations and well stimulation are designed for maximum flow rates and pressure generation capabilities. The frac pump should be easy to maintain in the field and durable, saving companies involved in hydraulic fracturing treatments both time and money.

How Can We Assist You in the Hydraulic Fracturing Process?

If you are working in hydraulic fracturing for oil and gas, you may require temporary stainless steel or carbon steel storage containers for the entire well cycle for exploration and production operations. Frac tanks help in the onsite storage of hazardous and non-flammable, non-corrosive liquids such as chemical additives, water, and wastewater.

Contact us or request a quote for the frac tank options, sizes, and costs.