Navigating the Flow: Mastering TDH Calculations for Your Rental Pump Needs

Whether you’re tackling temporary dewatering, transferring essential fluids, or managing complex waste and wastewater operations, finding the right rental pump is crucial. But beyond choosing the appropriate horsepower or flow rate, understanding Total Dynamic Head (TDH) is key to ensuring your pumping project runs smoothly and efficiently.

This article dives into the world of TDH calculations. We’ll empower you to:

- Demystify the TDH concept: Understand what it represents and how it impacts your pump selection.

- Master the calculation: Learn a step-by-step guide to determining the TDH requirements for your specific job.

- Optimize your rental: Choose the perfect pump rental that seamlessly matches your TDH needs.

- Unlock the power of synergy: Discover how pumps and tanks, including those available from Ironclad Environmental Solutions, collaborate to create holistic waste and wastewater solutions.

- Tap into expert guidance: Learn how Ironclad’s expertise can help you design and build a custom rental solution tailored to your unique challenges.

Demystifying TDH: The Heart of Your Pump’s Performance

Think of TDH as the pump’s total lifting capacity. It accounts for all the resistance the pump needs to overcome to effectively move the liquid from its source to its destination. Imagine climbing a hill while carrying water; the higher the hill and the heavier the water, the more effort you need. Similarly, pumps require more “effort” (head) to lift liquids higher and overcome frictional resistance in pipes and fittings.

Here’s what makes up TDH:

- Static Head: The vertical difference between the liquid source and its final destination (think climbing the hill).

- Friction Head: The energy lost due to friction between the liquid and the pump components and pipes (imagine rough concrete pipe vs. smooth PVC pipe vs. corrugated HDPE pipe, the rougher the surface the more friction head).

- Pressure Head: The desired pressure at the pump’s outlet to meet specific needs (think pushing the water out with enough force). 1 psi pump pressure = 2.31 feet of head of water.

By accurately calculating TDH, you ensure your chosen rental pump has the muscle to handle the job effortlessly. Selecting a pump with insufficient TDH can lead to:

- Reduced flow rates: The pump struggles to push the liquid, slowing down the process.

- Overheating and damage: The pump strains to meet the demand, potentially leading to breakdowns.

- Inefficient operation: Higher energy consumption due to the pump working harder than necessary.

- Cavitation: Involves the formation of water vapor bubbles that damage metal components when they collapse back to the liquid phase. It occurs because there is not enough pressure at the suction end of the pump, or insufficient Net Positive Suction Head available (NPSHa).

Mastering the Calculation: Your Step-by-Step Guide

Now, let’s equip you with the power to calculate TDH for your specific needs. Gather the following information:

- Vertical lift: Measure the height difference between the liquid source and its final destination in feet. Compare NPSHr to NPSHa

- Pipe length and diameter: Determine the total length and diameter of the pipes the liquid will flow through. Obtain pipe friction factor.

- Number and type of fittings: Identify the number and types of elbows, valves, and other fittings in the piping system.

- Liquid type: Specific gravity of the liquid you’ll be pumping (water, oil, etc.).

- Flow rate & Pressure Required: What is desired at the discharge point?

With this information, you can utilize the following formula:

TDH = Vertical Lift + (Friction Loss per 100 ft of pipe x Total Pipe Length in ft) + Fitting Loss

Remember, friction loss depends on several factors like pipe diameter, liquid viscosity, and flow rate. Consult pump manufacturer charts or online resources to find the appropriate friction loss value for your specific scenario.

Choosing the Perfect Rental Pump: Where TDH Meets Efficiency

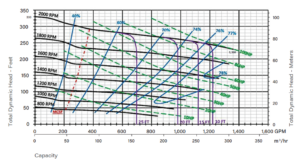

Once you have your TDH value, compare it to the performance curves of rental pumps available from Ironclad Environmental. Look for a pump with a TDH rating equal to or exceeding your calculated value to ensure smooth operation and optimal efficiency.

Ironclad’s extensive fleet of pumps caters to diverse needs, from high-volume dewatering to precise chemical dosing. Our expert team can guide you through the selection process, considering factors like:

- Flow rate requirements: How much liquid needs to be moved per unit time?

- Liquid properties: Is the liquid viscous, abrasive, or corrosive?

- Operational environment: Are there specific temperature or pressure requirements?

- Budget considerations: We offer flexible rental options to fit your project needs.

Remember, choosing the right pump rental goes beyond just matching TDH. Ironclad’s expertise ensures you get the perfect pump for your unique application, maximizing efficiency and minimizing costs.

Figure 1: The above graph is an example of a pump curve. Ironclad pump spec sheets have information on all available pump assets.

Beyond TDH: Synergy in Waste and Wastewater Solutions

While TDH focuses on pump performance, Ironclad Environmental Solutions understands that your needs often extend beyond a single piece of equipment. That’s where our comprehensive waste and wastewater solutions come into play. By combining powerful pumps with our diverse selection of rental tanks, we create holistic systems that tackle your challenges head-on.

For example, imagine needing to manage contaminated wastewater at a construction site. Ironclad can provide:

- High-performance pumps efficiently extract and transfer the wastewater.

- Durable tanks to safely store and contain the liquid for further treatment or disposal.

- Filtration systems that remove pollutants, ensuring compliance with environmental regulations.

- Expert guidance throughout the process, from initial planning to project completion.

This synergy between pumps and tanks extends to various applications, including:

- Industrial process water treatment: Recirculating and filtering process water for sustainable operations.

- Emergency spill response: Quickly containing and cleaning up accidental spills to minimize environmental impact.

- Disaster relief: Providing temporary wastewater treatment solutions in areas affected by floods or natural disasters.

Furthermore, Ironclad doesn’t just offer equipment; we offer expertise. Our team of experienced engineers and consultants can help you:

- Design a custom rental solution tailored to your specific needs and budget.

- Navigate regulations and permitting requirements.

- Ensure safe and efficient operation of your system.

- Provide ongoing support throughout your project.

Whether you’re facing a temporary challenge or require a long-term solution, Ironclad Environmental Solutions is your one-stop shop for reliable rental pumps, rental tanks, and comprehensive waste and wastewater expertise. Contact us today and let us help you navigate the flow towards a successful project.