Spill Control and Containment for Hazardous Materials

Spill control is the process of containing and managing the impact of environmentally detrimental spills on people and the environment. This process is key to safely handling hazardous materials, safeguarding the environment, protecting human health, and ensuring effective risk mitigation.

Understanding Spill Control, Containment, and Response

Spill control of minor hazardous material releases helps maintain environmental safety and compliance. Proper procedures and equipment help handle spills effectively, ensuring that hazardous chemicals don't pose a threat to people's health. By implementing the right spill control measures to prevent the sudden and accidental release of hazardous materials into the environment, businesses can prevent costly cleanups, avoid regulatory fines, and protect their personnel and surrounding communities.

Spill Control vs. Secondary Containment

While spill control involves the immediate response to contain and manage a spill, secondary containment is the equipment that catches and contains the entire spill, ensuring 100% protection. Secondary containment can include spill pallets and drip trays, which are crucial for preventing leaks and spills from reaching the environment if the primary container fails.

Types of Spills

Understanding the types of spills is crucial for determining the appropriate response and equipment needed.

- Small spills, leaks, and drips, which are more manageable, can often be contained and cleaned up using spill kits.

- Larger, more hazardous spills, such as chemical and oil spills, require specialized equipment and expertise to control.

Our equipment is designed to handle smaller spills, ensuring safe and efficient containment.

Important Regulations and Guidelines

Adhering to federal regulations like the Spill Prevention, Control, and Countermeasure (SPCC) rule is mandatory for effective spill containment.

Regulated under the Clean Water Act and Oil Pollution Act, the SPCC outlines the framework for oil spill prevention, preparedness, and response, aiming to "prevent oil from reaching navigable waters and adjoining shorelines, and to contain discharges of oil" (EPA.gov).

The EPA provides guidelines for facilities that must implement these plans. Compliance with these guidelines not only ensures environmental protection but also demonstrates a company's commitment to responsible operations.

Essential Spill Control Products and Methods

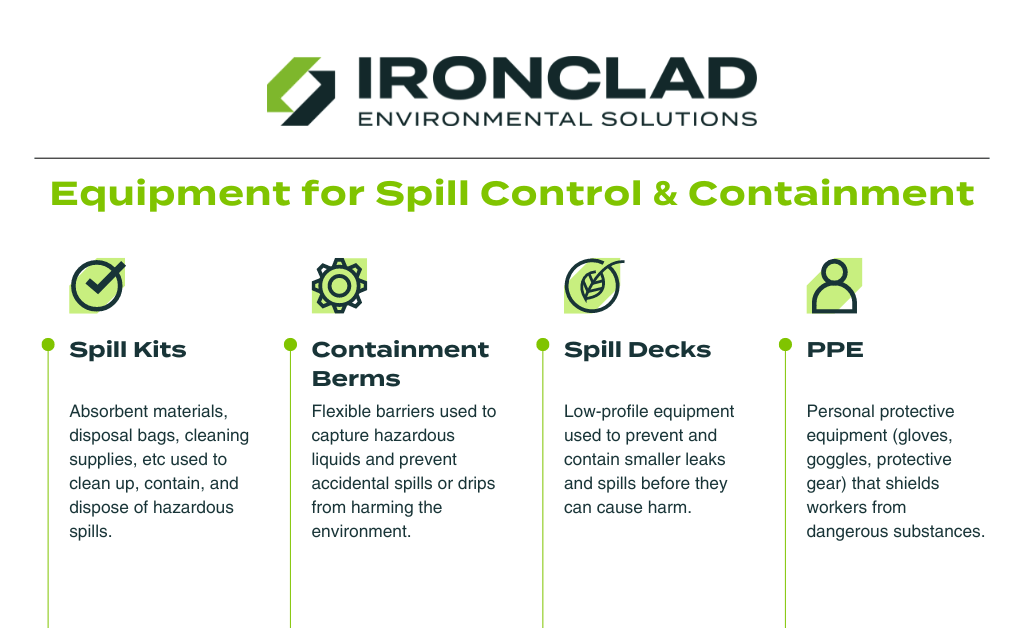

Spill Kits and Containment Berms

Spill control kits and containment berms are important assets for managing spills.

- Spill Kits: Tools used to clean up, contain, and dispose of hazardous spills. They typically include absorbent materials, disposal bags, cleaning supplies, and personal protective gear, providing a comprehensive solution for immediate spill response.

- Containment Berms: Flexible barriers designed to capture liquids and prevent accidental spills or drips. Our berms are designed for agricultural, industrial, or commercial facilities that use or transfer oil and other hazardous materials.

These assets are essential for ensuring environmental compliance and preventing the accidental release of hazardous chemicals. We help businesses stay compliant by providing top-quality solutions that effectively manage these materials.

Spill Decks

Spill decks are also designed to prevent and contain smaller leaks and spills effectively. These low-profile platforms can hold containers of hazardous substances, catching any leaks or drips before they can cause harm. By incorporating spill decks into your spill control strategy, you can ensure that even minor leaks are managed promptly.

Personal Protective Equipment (PPE)

Personal protective equipment is necessary for workers handling hazardous materials and conducting spill-cleanup operations. PPE includes items such as gloves, goggles, and protective gear, which shield workers from exposure to dangerous substances. Ensuring that all personnel are equipped with the appropriate PPE not only protects their health but also ensures that spill response activities are done safely, minimizing the risk of injury or contamination.

Best Practices for Spill Containment

Regular Maintenance and Storage of Chemicals

Preventing spills starts with regular equipment maintenance and proper storage of hazardous liquids. Ensuring that equipment is regularly inspected and maintained reduces the likelihood of leaks and malfunctions.

Proper Planning and Setup of Containment Systems

Conducting a thorough site assessment is a critical step in the spill control process. This allows companies to select the most appropriate containment solutions tailored to the specific needs of their site. Implementing robust containment systems ensures that any potential spills are quickly contained and managed.

Having a well-developed response plan is also crucial. This plan should detail the steps that should be taken in the event of a spill, ensuring a response that minimizes environmental impact and protects human health.

Employee Training

Employee training is the final best practice for effective spill containment. Making sure the response team is trained to handle hazardous materials, emergency response procedures, and the use of personal protective equipment is essential. Regular training sessions help employees stay prepared and confident in their ability to respond to spills quickly. This doesn't just improve workplace safety; it ensures compliance with regulatory requirements and promotes a culture of safety on the job site.

By following these best practices, businesses can reduce the risk of spills, ensuring a safer working environment for all.

Reliable Containment with Ironclad Environmental Solutions

At Ironclad Environmental, our industrial spill containment berms are designed to capture leaks, drips, and small spills during hose coupling/uncoupling or from slow leaks from valves. These berms provide users with enough response time to react and repair without the contents reaching the ground.

Our containment solutions can be used for steel tanks, roll-off boxes, drums, pumps & other internal combustion-powered equipment, ensuring environmental compliance through effective spill containment. Whether in agricultural, industrial, or commercial facilities, our berms are designed to prevent accidental releases to the ground, protecting the environment and your operations.

Industry-Leading Specialty Containment Solutions

As the largest specialty containment company in the United States, we are committed to providing solutions that meet specific project needs. Our comprehensive solutions ensure that businesses can manage hazardous materials safely and efficiently, maintaining compliance and preventing environmental damage.

Rent Berms, Tanks, and Boxes with Ironclad Environmental

To avoid the costs of spill cleanups, it’s crucial to consider the type of equipment you rent. That’s where Ironclad Environmental comes into play. We encourage you to always rent berms along with steel tanks, roll-off boxes, and pumps to ensure comprehensive spill management.

Rent Spill Containment Berms

Ensure your operations are safe, compliant, and environmentally responsible.

Resources:

- Environmental Protection Agency. https://www.epa.gov/

- OSHA. https://www.osha.gov/