Understanding Sludge Dewatering Processes

Sludge dewatering is the process of removing water from sludge, resulting in a concentrated solid that is easier and more cost-effective to dispose of. This process is crucial for wastewater treatment plants, construction sites, and industrial facilities because it helps reduce disposal costs and minimize environmental impact.

Deep Dive into Sludge Dewatering

Sludge forms as a byproduct during various municipal and industrial processes, where solid particles settle out from liquids, creating a dense mixture that is often difficult to manage.

The sludge dewatering process involves transforming this mixture into more cost-effective, solids filter cakes. It reduces the volume of waste, making it easier to handle, transport, and dispose of. By efficiently separating the solid and liquid components, wastewater treatment plants can streamline their operations.

The Dewatering Process

To effectively and safely dewater sludge, it's important to follow the following steps:

- Begins with a thorough examination of the water, determining the type of sludge treatment process required.

- Necessary permits are then obtained to ensure the process complies with environmental regulations.

- Specialized dewatering boxes are rented and brought to the site - essential for separating the liquids and solids.

Reducing the moisture content in sludge is key to effective volume reduction. Lowering the water content not only decreases the overall volume of the sludge but also reduces its weight, making transportation and disposal more economical.

Sludge Dewatering Applications

In construction sites, sludge dewatering ensures that the site remains safe and compliant by managing the waste generated during excavation and other processes.

For industrial projects, dewatering is used for handling byproducts and waste efficiently, ensuring that operations run smoothly with minimal environmental impact.

Wastewater treatment plants rely on dewatering to manage the large volumes of sewage sludge produced during the treatment process.

Across all these applications, sludge dewatering plays an integral role in maintaining the overall efficiency and sustainability of the project.

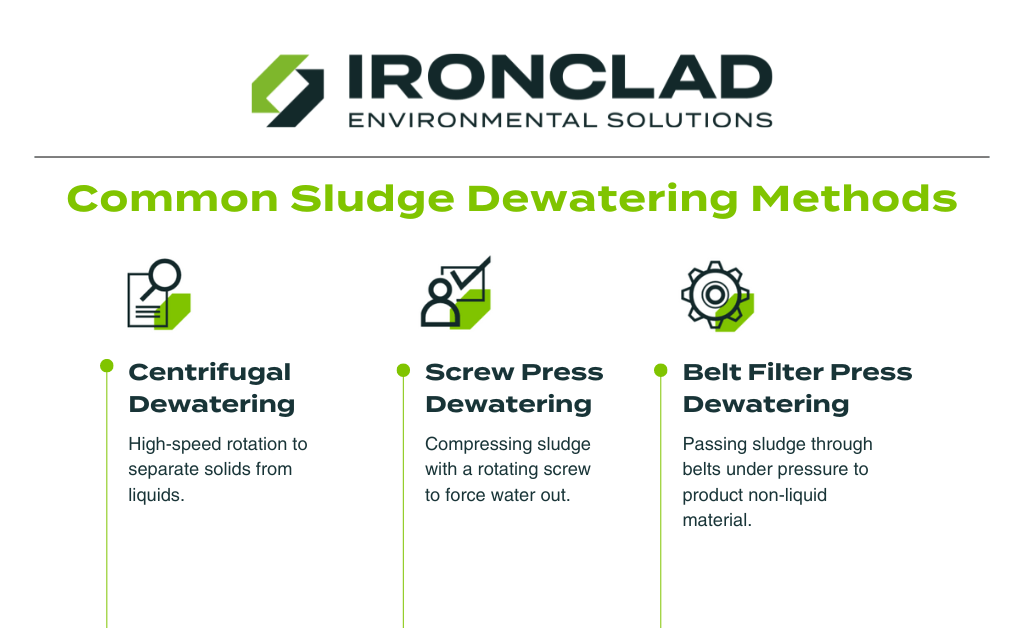

Common Sludge Dewatering Methods

Mechanical Dewatering

Mechanical dewatering is one of the most effective ways to remove water from sludge. It involves processes like centrifugal dewatering, screw press, and belt filter press.

- Centrifugal dewatering uses high-speed rotation to separate solids from liquids.

- Screw press dewatering involves compressing the sludge through a rotating screw to force water out.

- Belt filter press dewatering involves passing wastewater sludge through a series of belts under pressure to produce non-liquid material.

Each of these methods offers advantages and faces certain challenges in terms of efficiency, operating costs, and the amount of water removal they can achieve. Choosing the appropriate method requires balancing these factors to meet the specific needs of the project.

Filtration Technologies

Filtration systems are used to polish water or liquids by removing the minimal amount of solids remaining in the fluid. Unlike mechanical dewatering, where the primary goal is to concentrate solids for their end use or disposal, filtration focuses on refining the liquid for further use, treatment, or disposal.

By eliminating even the smallest particles from the liquid, these methods ensure that the treated water meets stringent quality standards.

Working with Experienced Solution Providers

Given the complexities and challenges associated with sludge dewatering, it's essential to partner with an experienced provider who understands these methods and technologies. A skilled provider will assess the specific needs of the project, recommend the right equipment, and make sure that the dewatering process is executed efficiently.

Working with a trusted partner is key to achieving the best possible outcomes for your wastewater management project.

Factors Influencing the Dewatering Process

Sludge Characteristics

The efficiency of the dewatering process is influenced by the characteristics of the sludge itself. Key factors include:

- Solids content

- Moisture content

- Particle size

- Particle shape

Sludge Content

Sludge with a higher solids content is generally easier to dewater because there is less water to remove. Conversely, sludge with a higher moisture content requires more effort and time to achieve the desired dryness.

Operational Considerations

Operational considerations involve dewatering's impact on operating costs and sludge disposal. Efficient dewatering can reduce the volume of sludge, therefore lowering disposal and transport costs.

However, the choice of dewatering method and the condition of the sludge can affect these costs. Methods that require high energy consumption or frequent maintenance may also increase operating expenses.

Benefits of Effective Sludge Dewatering

Cost and Environmental Benefits

By reducing the volume of sludge, dewatering minimizes disposal costs, making waste minimization more efficient and economical.

Additionally, this process restores the capacity of surge basins, stormwater ponds, and fire water ponds by removing and dewatering accumulated sediment from the impoundment. It plays a role in safe wastewater treatment and sludge disposal practices by making the waste easier to handle, treat, and dispose of.

Impact on Wastewater Treatment Plants

For wastewater treatment plants, sludge dewatering helps maintain operational efficiency. Reducing the volume and moisture content facilitates the efficient and cost-effective transportation and disposal of the dewatered filter cake.

In the long term, dewatering contributes to improved environmental compliance. By adhering to environmental regulations through proper sludge management, these sewage treatment plants can avoid potential fines and maintain their reputation for responsible operations.

Industry-Leading Assets for Safe & Effective Sludge Dewatering

Ironclad Environmental understands the complexities of managing and transporting waste, and our expertise allows us to recommend the right equipment and strategies to treat waste materials safely. Our team works closely with clients to make sure their needs are met.

Our Dewatering Box Rentals

We offer a comprehensive range of assets and equipment in various sizes, including our dewatering boxes and vacuum boxes. We offer both boxes in 20 and 25 YD, and also 30 YD for dewatering boxes.

We deliver and set up these boxes directly on the project site, allowing for seamless integration into your operations. Once the dewatering process is complete, the boxes can be easily transported to the disposal facility. We always conduct detailed testing on our equipment to ensure it operates at top performance, providing clients with reliable, effective solutions every time.

Safety as a Top Priority

With every project we take on, safety is our number one priority. We approach each job with a commitment to protecting our clients, their teams, and the environment. That's why companies continue to trust us to handle every aspect of their project with the utmost care and attention to safety.

We Provide the Expertise and Assets You Need

Discover how we can support your project with safe, efficient, and industry-leading dewatering solutions.

Resources:

- Environmental Protection Agency. https://www.epa.gov/