How to Choose the Right Dewatering Media: The Bucket Test Explained

Testing for the right media for a dewatering box starts with a bucket test. This test helps determine if a specific dewatering filter media can effectively separate solids from your sample liquid, ensuring that dewatering is effective for a given job site. Whether you're managing wastewater, sludge, or sediment, selecting the right media is key for efficiency and compliance - and the bucket test is a reliable field method to identify the best dewatering solution for your specific requirements.

What is the Bucket Test and Why is it Important?

A bucket test is a quick and effective way to evaluate passive gravity dewatering technology in dewatering boxes.

Industries such as construction, industrial wastewater treatment, and stormwater management rely on dewatering boxes to physically separate sediment, sludge, and other waste materials, so it's important to select the correct media to keep operations efficient, compliant, and cost-effective.

Key Benefits of the Bucket Test

- Reduces trial and error - A small-scale test prevents costly mistakes by verifying dewatering performance before full-scale implementation.

- Ensures compliance - Proper dewatering helps meet waste control regulations and project-specific discharge requirements.

- Optimizes efficiency - Identifying the right dewatering media upfront reduces clogging, improves drainage systems, and streamlines operations.

- Saves time and costs - Prevents unnecessary equipment modifications and disposal expenses by selecting the correct dewatering media from the start.

By using the bucket test method, businesses can make informed dewatering choices, improving waste management efficiency and regulatory compliance while avoiding costly disruptions.

Step-by-Step: Performing the Bucket Test

By replicating real-world dewatering conditions on a small scale, the bucket test helps you determine the most effective solution before full implementation.

Materials Needed

To perform a bucket test, you need the following:

- 5-gallon paint bucket - serves as the test container.

- Strainer or colander - supports the dewatering media during testing.

- 2x2-foot square samples of each filter media - compare performance in cloth fibers and screen weave knit mesh media to ensure proper sediment control.

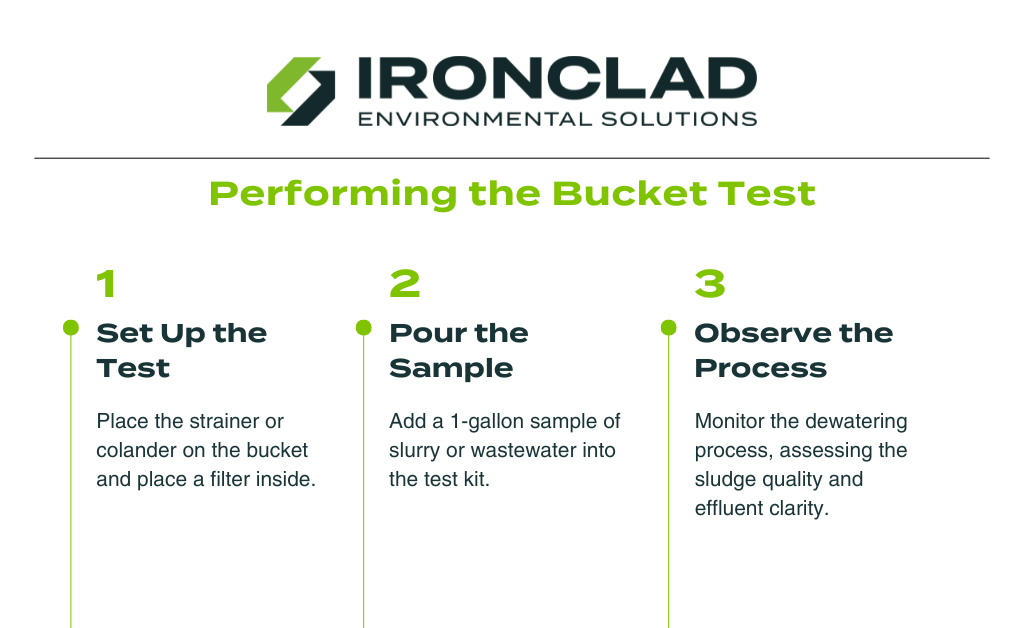

Testing Procedure

- Set up the test: Place the strainer or colander on top of the bucket and place a dewatering media sample inside.

- Pour the sample: Slowly add a 1-gallon sample of slurry or wastewater into the media-lined test kit.

- Observe the dewatering process: Monitor how the liquid drains through the media over time. The process can take anywhere from a few days to weeks, depending on the material being dewatered. Assess the quality of the dewatered sludge and the clarity of the effluent to determine its effectiveness.

Additional Recommendations

- Perform the test on the project site: Conducting the test at the construction site provides the most accurate results while avoiding unnecessary waste handling or disposal issues.

- Refine the process if needed - If the initial filtrate quality is inadequate, perform additional vacuum filtration tests to enhance effluent clarity and improve dewatering efficiency.

By following these step-by-step instructions for the dewatering bucket test, businesses can select the right dewatering media - ensuring compliance, efficiency, and cost savings in their dewatering operations.

Interpreting Results: Selecting the Best Filtration Equipment

Once the bucket test is complete, the next step is to evaluate performance and determine the best dewatering solution for your project. Proper interpretation of the test results ensures that your dewatering boxes function efficiently, minimizing waste disposal challenges and keeping operations compliant.

Evaluating Performance

Assess Effluent Quality

The first part of evaluating performance is assessing effluent quality. Clearer effluent indicates that dewatering was effective, while excessive cloudiness suggests the need for a finer dewatering media.

Check Sludge Consistency

Well-dewatered sludge should be solid and manageable after the testing process. If it remains too wet, a different dewatering media may be required.

Identify Filtration Issues

Lastly, watch for dewatering media blinding (clogging) or poor sediment removal, which can impact overall system performance.

Filter Recommendations

Adjust Filtration Setup

If the bucket test results show inadequate separation, consider using additional vacuum filtration or filter media to improve performance.

Select Equipment Based on Material Compatibility

The right media should be suited to your specific waste stream, project needs, and regulatory requirements to ensure effective dewatering.

By carefully analyzing bucket test results, businesses can optimize dewatering operations, reduce compliance risks, and ensure cost-effective waste management.

Expert Dewatering Solutions with Ironclad Environmental

Navigating the complexities of wastewater treatment requires a partner with proven expertise and reliable resources. At Ironclad Environmental, we offer comprehensive dewatering solutions tailored to your project's unique needs. From equipment rental and setup to on-site support and recommendations, our team ensures efficient and compliant operations from start to finish.

Our extensive rental inventory includes:

- Dewatering Boxes: Equipped with specialized solids separation and drainage systems to effectively separate liquids from slurry or sludge, facilitating easier transport and disposal. Includes dewatering roll-offs, metal lid dewatering roll-offs, and vacuum roll-off dewatering boxes.

- Filtration Systems: Our high-performance bag filters manage filtration from 20 microns down to 1 micron, effectively addressing the most challenging dirty water conditions.

- Other Specialty Containment Assets: From steel frac tanks to roll-off boxes, we provide a variety of equipment to meet the demands of construction, industrial wastewater management, stormwater management applications, and more.

Our team works closely with your team to design and assemble a complete filtration system that safely meets your specific project's needs and discharge requirements. By conducting on-site consultations, we ensure that our solutions are customized to your operational challenges - further promoting efficiency and regulatory compliance.

Request a Quote to Rent Dewatering Equipment

Renting specialty containment assets from Ironclad means benefitting from our commitment to quality, environmental safety, and customer satisfaction. Our vertically integrated solutions offer upfront pricing with no hidden fees, and our rigorously tested equipment guarantees top performance on your job site.

Ready to optimize your dewatering operations? Request a quote today or speak with an expert to discover the right filtration solutions for your project.