IronMax Tanks: Large-Scale Modular Storage Solutions for Industrial Applications

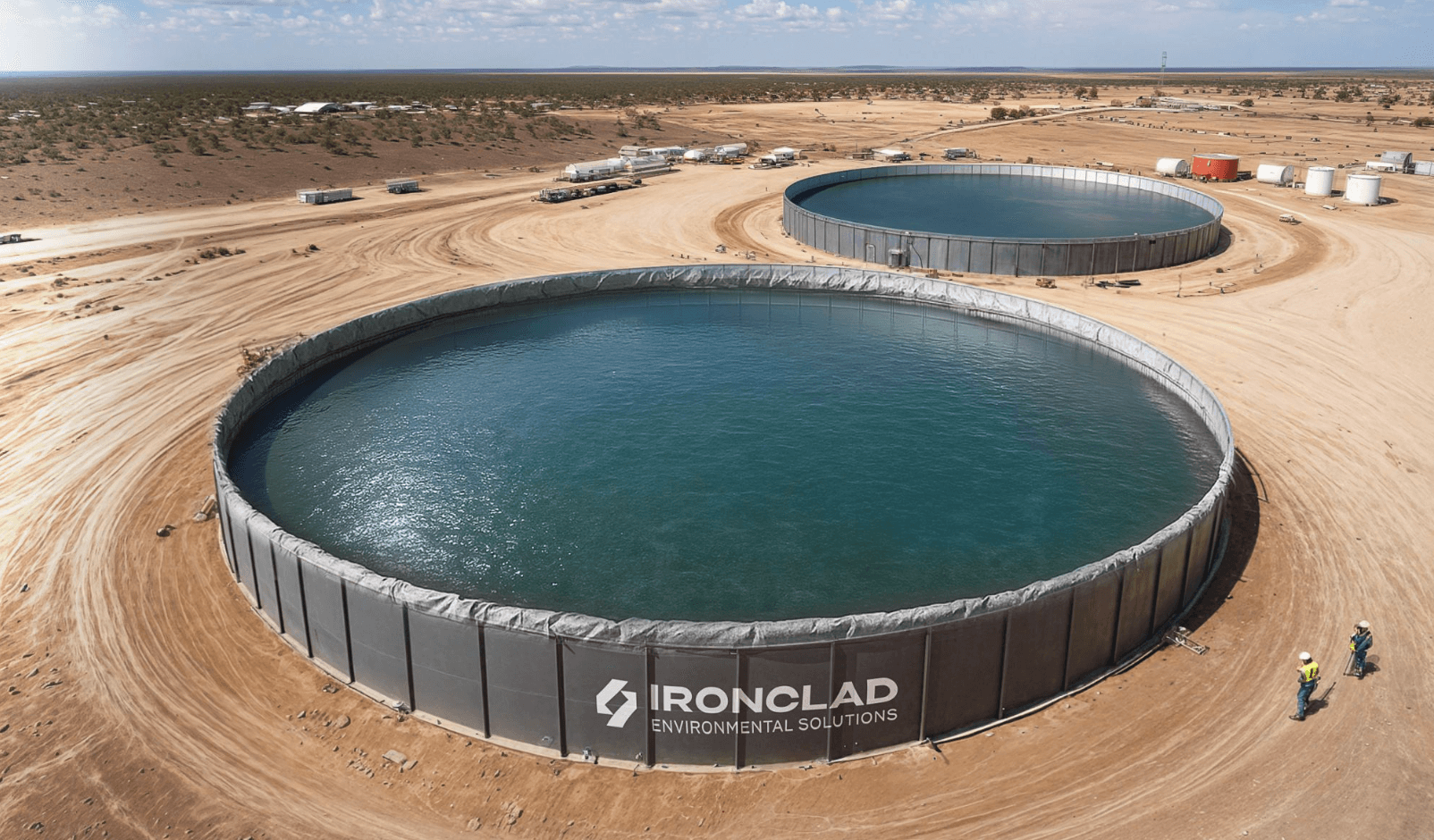

When big projects call for water or fluid storage at large volumes, standard tanks just won't cut it. The IronMax Tank, Ironclad's modular above-ground storage tank, offers a bigger and better solution.

Boasting industrial-strength capacity of up to 2.5 million gallons, as well as a modular design that provides the flexibility required by demanding job sites, the IronMax Tank is purpose-built for projects that need non-potable liquid storage – and the ability to scale up or down as job needs change. From oil field operations to environmental remediation, our IronMax Tanks deliver storage solutions that keep projects moving and compliant.

What's an IronMax Tank?

The IronMax Tank is a modular above-ground storage system designed for large-scale, temporary, or semi-permanent liquid containment. Built from curved steel panels and assembled on-site, each tank offers a range of capacities from 500,000 gallons–2.5 million gallons.

Unlike conventional tanks, IronMax units can be rapidly deployed, scaled, and removed without permanent infrastructure, making them ideal for industrial applications that demand flexibility, durability, and massive volume. From the oil and gas to construction and even the food processing industry, the IronMax Tank is the liquid-storage solution you need.

Technical Specifications & Configurations

The IronMax Tank delivers exceptional performance thanks to an engineered design using premium materials. Understanding these technical elements helps project managers select the right configuration for their specific containment requirements.

Capacity Range

IronMax Tanks are available in five standard configurations to meet virtually any non-potable liquid storage requirement:

| Barrels | Gallons | Approximate Diameter |

|---|---|---|

| 18,000 | 756,000 | 105' |

| 26,000 | 1,130,000 | 126' |

| 41,000 | 1,722,000 | 157' |

| 60,000 | 2,520,000 | 189' |

The IronMax's largest configuration provides an impressive ~2.5 million gallons of storage capacity. This minimizes transport requirements, cutting down on over-the-road.

Construction Elements

The IronMax Tank utilizes a simple but effective design to provide massive storage capacity while maintaining transportability:

- Curved Panels: Curved steel panels seamlessly connect with each other to form a circular structure; total size of the IronMax Tank is determined by the number of panels utilized.

- Liner System: Single or double-layer liners are secured in place with a simple clamp system, creating a watertight structure. Double liners may be used for additional protection in sensitive applications; an assortment of liner options can meet the requirements of different chemicals and temperatures.

- Geomembrane: A geomat can be placed beneath the liner to provide additional protection against leakage and ground contamination.

- Optional Covers: For specific applications and site needs, floating lids or bird netting can be added to the top of the tank.

The beauty of the design is simplicity. Each component can be transported on standard trucks and assembled on-site, creating massive storage capacity without the logistical challenges that come with transporting oversize, pre-built tanks. The modular nature allows for installation in remote locations or areas with difficult access, where traditional large-volume tanks would be impossible to deploy.

Installation & Deployment

The value of the IronMax Tank emerges through efficient installation, which delivers significant storage capacity in a fraction of the time required for conventional construction. This directly supports project timelines and budgets.

Site Preparation Requirements

Proper site preparation is essential for optimal performance and longevity of IronMax Tank installations:

- Graded Surface: Compaction is required on the job site, which must be properly graded to create a level foundation

- Drainage Planning: Appropriate drainage solutions must manage precipitation around the tank perimeter

- Access Routes: Sufficient clearance for delivery vehicles and installation equipment

- Utility Coordination: Marking of any underground utilities prior to site preparation

- Environmental Protection: Implementation of erosion control measures as required by local regulations

The Ironclad team will provide detailed site preparation specifications based on your specific project requirements.

Assembly & Installation

With Ironclad, you don’t have to worry about tank assembly. We coordinate the entire installation process through trusted third-party partners who specialize in IronMax deployments:

- Professional Site Assessment: Our team works with you to evaluate the prepared site and ensure it meets installation requirements.

- Coordinated Delivery: All system components are scheduled and delivered in alignment with your project timeline.

- Expert Assembly: Our installation team handles tank assembly, liner placement, and system setup.

- Quality Assurance: Every install includes thorough inspection protocols to verify structural integrity and prevent leaks.

- System Activation: The tank is initially filled with a minimum of 18" of water to ensure proper liner tension and operational stability. Need help with water transfers? We'll manage that, too.

- Ongoing Monitoring: Ironclad offers level monitoring options and leak detection throughout your job duration.

- Ability to Nest: For storage of particularly dangerous or sensitive materials, clients looking for extra peace of mind can nest IronMax Tanks, with the exterior structure providing 150% capacity of the interior tank.

- Custom Solutions: Aeration units, heating options, and baffle curtains are available to meet the unique needs of your job site.

Most IronMax installations are completed within a day — significantly faster than conventional built-in-place alternatives — helping you minimize site disruption and accelerate project schedules.

Operational Requirements

To maintain optimal performance throughout deployment, IronMax Tanks have specific operational requirements:

- Minimum Water Level: A minimum of 18" of water must be maintained in the tank at all times to ensure proper tension and structural integrity

- Periodic Inspection: Regular assessment of liner condition and panel connections

- Weather Monitoring: Increased vigilance during extreme weather events

- Water Quality Management: Depending on storage duration, water quality monitoring may be necessary

These requirements ensure the system performs as designed, regardless of duration or environmental conditions.

When your project wraps, Ironclad can step in to treat remaining water and coordinate the safe disposal of liners, geomats, and other temporary materials — all handled through our certified waste management partners.

Primary Applications for IronMax Tanks

IronMax Tanks excel on jobs where conventional liquid storage solutions fall short due to volume requirements, deployment constraints, or project duration uncertainty. These specialized systems serve critical roles across multiple industries and specific applications.

- Pipeline Hydrotesting: Large-volume water storage for LNG and other pipeline pressure testing

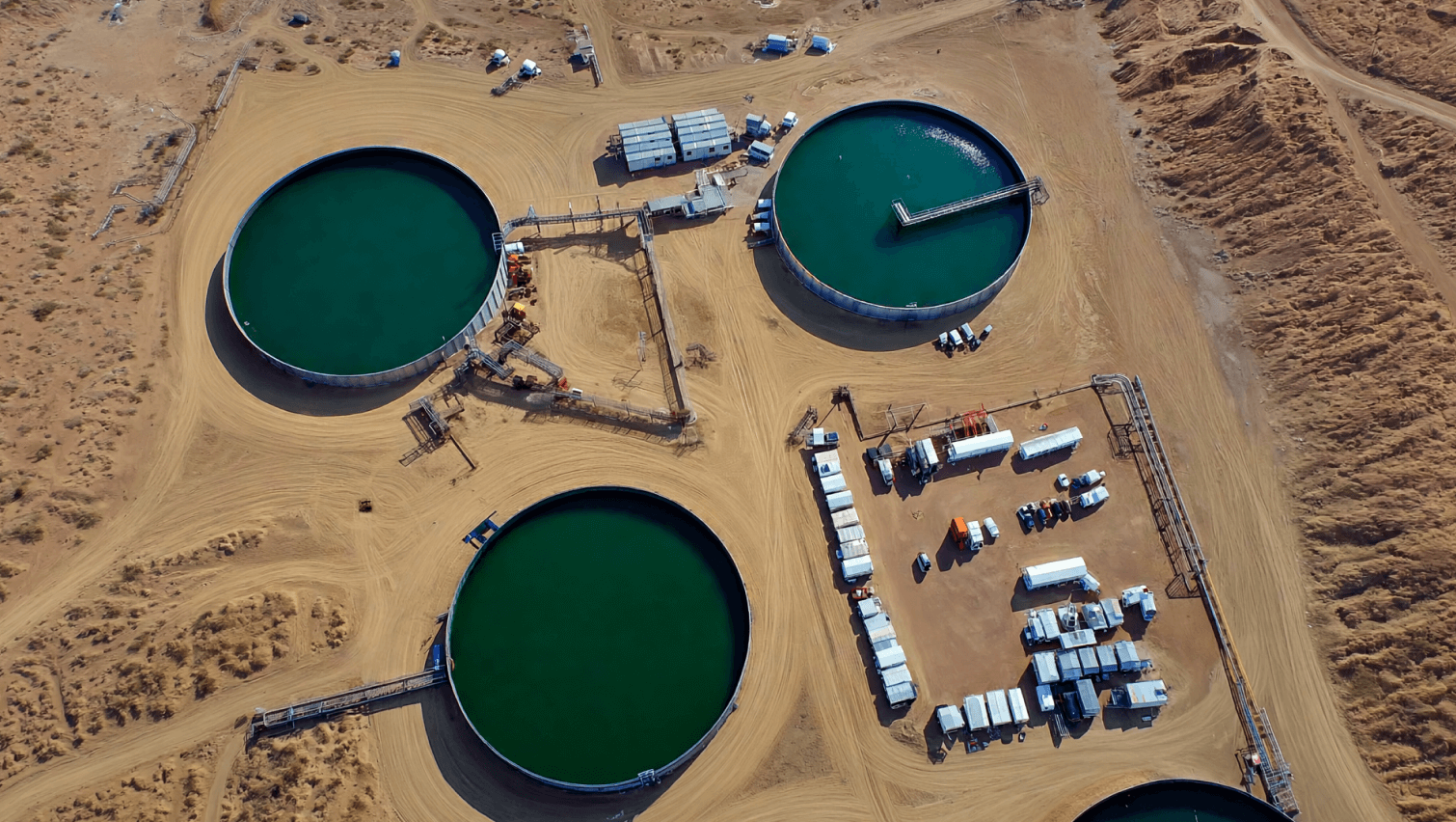

- Drilling Fluid Management: Temporary storage of drilling fluids for multiple wells within close proximity

- Produced Water Handling: Storage of production water awaiting treatment or disposal

- Frac Water Storage: Source water containment for hydraulic fracturing operations

- Secondary Containment: Large-scale backup containment for existing storage infrastructure

- Fire Suppression Systems: Temporary water reservoirs for fire protection during construction phases

- Erosion Control: Source water for dust suppression and erosion prevention measures

- Dewatering Operations: Storage for water removed from large excavations

- Stormwater Management: Collection and controlled release of stormwater from construction sites

- Hydrotest Discharge: Temporary storage for water used in system testing before proper disposal

- Dust Suppression: Store water to support dust suppression on the large, remote job-sites required for the construction of solar farms

- Remediation Projects: Water storage during cleanup of contaminated sites

- Settling Pond Transfers: Temporary storage during maintenance of permanent settling ponds

- Facility Maintenance: Water storage during cleaning or repair of permanent tanks

- Agricultural Irrigation: Seasonal water storage for large-scale agricultural operations

- Emergency Response: Rapid deployment water storage for disaster response scenarios

The versatility of the IronMax Tank makes it ideal for any situation requiring large-volume water and liquid storage in remote or isolated locations. Their modular design allows for a single installation with ongoing use throughout project duration, eliminating the logistical complexity of manifolding numerous smaller tanks together.

Ready to Solve Your Large-Scale Storage Challenges?

When standard storage solutions won't meet your needs, the IronMax Tank delivers unmatched value through four key advantages:

- Rapid Deployment & Removal

Our modular system can be quickly built — and just as easily disassembled when the job is complete. This eliminates the lengthy construction timelines of permanent solutions while providing the flexibility to adapt as project needs evolve. - Massive Capacity — Anywhere

With the ability to store up to 2.5 million gallons anywhere with flat, graded ground, the IronMax Tank brings unprecedented storage capabilities to remote or challenging locations that would otherwise require complex infrastructure development. - Simpler Than Multiple Tank Systems

Rather than manifolding 120-plus frac tanks together—with all the associated connections, maintenance points, and failure risks—a single IronMax Tank provides a streamlined storage solution with fewer components and management requirements. - Reduced Transportation & Labor Costs

The IronMax Tank can be delivered in significantly fewer trips than alternative solutions. This translates to lower transportation expenses, reduced carbon footprint, and substantial labor savings throughout the deployment lifecycle.

Our expert team is ready to assess your specific requirements and provide a customized storage strategy that leverages these advantages for your operation.

Request a Quote Today to learn how Ironclad's IronMax Tank can keep your project moving forward, while ensuring complete environmental compliance.