What Causes Water Hammer – Understanding the Problem and Preventing Damage

Water hammer is a loud banging noise or pressure surge that happens after a sudden change in water flow within an industrial piping system, which can damage equipment and disrupt operations.

For example, in a pump and hose/pipe system, quickly shutting off a valve can cause water to surge back through the pipe, leading to significant forceful surges and environmental contamination. Understanding water hammer's effects is crucial for preventing extensive damage and maintaining system efficiency.

What is Water Hammer and What are the Causes?

Water hammer, also called hydraulic shock, is a serious issue in industrial water management. It occurs when water flow suddenly changes, creating high-pressure pulses that lead to equipment damage and leaks.

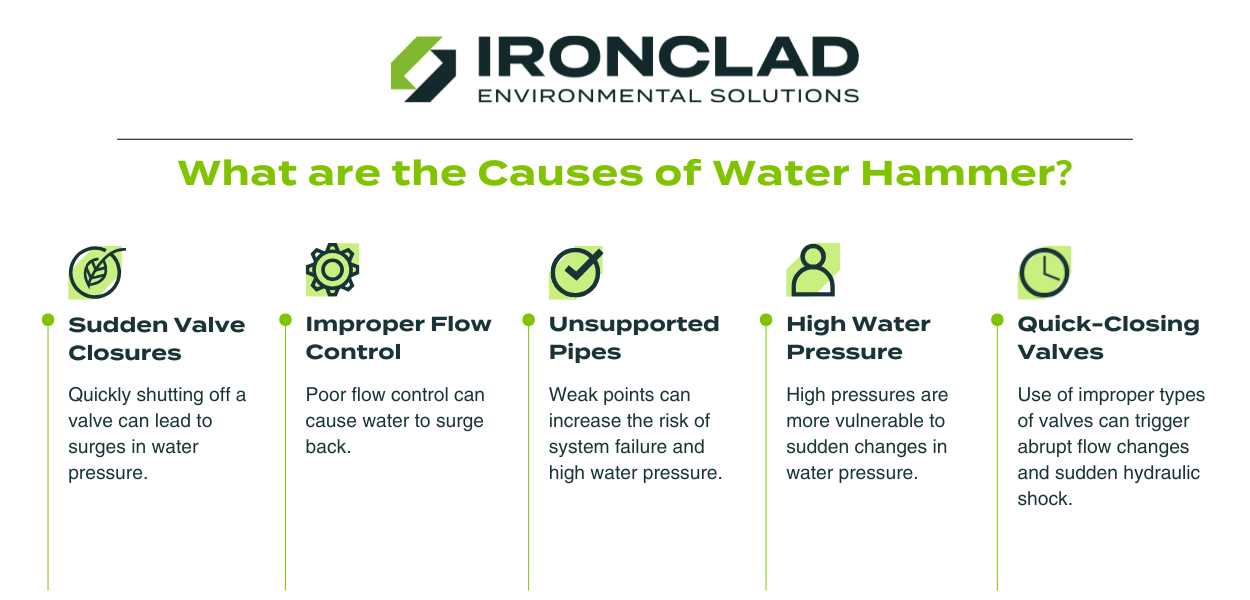

Several factors can trigger water hammer, including:

- Sudden valve closures - Quickly shutting off a valve can create a surge of water pressure, leading to damaging shockwaves.

- Improper flow control in tank systems - Poor regulation can cause water to surge back, with a sudden spike in pressure to the system.

- Loose or unsupported pipes - Weak points in the system can increase the risk of system failure.

- Excessive water pressure - High-pressure conditions can make systems more vulnerable to sudden hydraulic surges.

- Faulty or quick-closing valves - An improperly specified valve can trigger abrupt flow changes, contributing to hydraulic shock.

Understanding these causes is crucial for preventing damage and ensuring smooth, efficient operations.

Ramifications of Water Hammer in Industrial Operations

Water hammer isn't just a minor inconvenience - it can have serious physical and operational consequences. The sudden hydraulic surge puts stress on piping systems, storage tanks, and infrastructure. Left unaddressed, water hammer can lead to costly repairs, unplanned downtime, spills, and environmental damage that disrupts day-to-day operations.

Structural Damage

Repeated pressure surges can weaken infrastructure over time - leading to burst pipes, cracked tanks, and compromised containment systems. These failures present environmental and safety risks, especially in industries handling hazardous materials.

Process Disruptions

Water hammer can cause spills, splashback, and uncontrolled surges that interfere with critical processes. In high-volume operations, even a short disruption can affect project efficiency.

Increased Wear and Tear

Valves, pressure tanks, and other system components bear the brunt of fluctuating water pressure. Over time, the continuous stress increases the likelihood of leaks, malfunctions, and costly equipment replacements.

Wasted Resources

Leaks and overflows caused by sudden pressure waves can result in significant water loss, increasing operational costs for the operation.

Costly Repairs and Downtime

When water hammer damages infrastructure, the result is often expensive repairs and unplanned downtime. For businesses reliant on uninterrupted operations, this can mean lost revenue and higher maintenance costs.

By understanding the risks of water hammer, you can take proactive steps to protect your systems, minimize costly damage, and maintain reliable, efficient operations.

How to Prevent Water Hammer Effectively

System Modifications

Making targeted adjustments to your systems can help absorb pressure waves and prevent sudden surges:

- Install water hammer arrestors - These devices absorb pressure spikes, preventing shock waves from traveling through the system.

- Use check valves, float valves, and air-relief valves - These components regulate water movement, preventing sudden stops and maintaining a controlled flow.

- Adjusting pressure regulators - Keeping water pressure within optimal levels reduces the likelihood of hydraulic shock events.

Best Practices

Small changes in how equipment is used can significantly reduce stress on the system:

- Close valves gradually - Quick valve closures are one of the biggest triggers of water hammer - implementing controlled shut-off procedures helps prevent surges.

- Perform regular maintenance - Inspecting shut-off valves, pressure tanks, and containment systems ensures they remain in good condition and can handle pressure shifts effectively.

Specialized Equipment Recommendations

Certain equipment is better suited to withstand water hammer and minimize its effects. For example, metal tanks are more resistant to pressure fluctuations than plastic alternatives, reducing the risk of damage caused by hydraulic shock.

Debris in water lines can also worsen pressure spikes. Installing a filtration system helps maintain smooth flow and prevents particles from interfering.

Why Proactively Addressing Water Hammer Matters

Waiting until water hammer causes a system failure isn’t an option for industrial operations. Proactively managing hydraulic shock ensures long-term system reliability, minimizes operational risks, and prevents costly repairs.

- Avoiding risks before they escalate - Implementing preventative measures ensures that minor fluctuations in water pressure don't turn into full-scale operational disruptions.

- Protecting assets and infrastructure - Businesses can extend the lifespan of their hoses, valves, and containment systems, reducing hefty damage costs to their rental equipment.

- Enhancing efficiency - A well-managed system operates more efficiently, saving resources and keeping facilities compliant with industry standards.

Proactively managing water hammer isn’t just about avoiding damage - it’s about creating a more stable, efficient, and cost-effective operation that supports long-term success for the business.

How Ironclad Environmental Helps Solve Water Hammer Issues

At Ironclad Environmental, we understand the challenges that water hammer presents. With years of experience in water management and containment, we help businesses across various industries protect their equipment and maintain operational efficiency.

We offer the largest fleet of specialty containment assets - including frac tanks, roll-off boxes, water pumps, filtration systems, pipes, hose fittings, containment berms, and more - all designed to prevent damage caused by water hammer. Whether you're dealing with sudden pressure fluctuations or need a system optimized for stable water flow, our equipment offers reliable performance in the most demanding environments.

Tailored On-Site Services

Beyond equipment rentals, we provide on-site assessments and tailored solutions to address water hammer and other operational challenges. Our team works closely with you to ensure your system is reinforced against sudden pressure changes - reducing the risk of costly downtime and repairs.

Every piece of equipment we offer is built for long-term stability and efficiency, helping businesses optimize their operations while avoiding environmental hazards, regulatory fines, and unnecessary expenses.

Speak to an Expert

Don’t let water hammer put your operations at risk. Speak to an expert at Ironclad Environmental today to find the right containment solutions for your facility.